Sharon Fieldhouse | Clifton Forge, VA

designbuild/LAB (2013-2014)

Personal Contributions: Design of prefabricated modules, foundation and roof connection details, structural detailing, project scheduling, structural component fabrication, material takeoffs and roof framing.

Photographs by Jeff Goldberg/ESTO

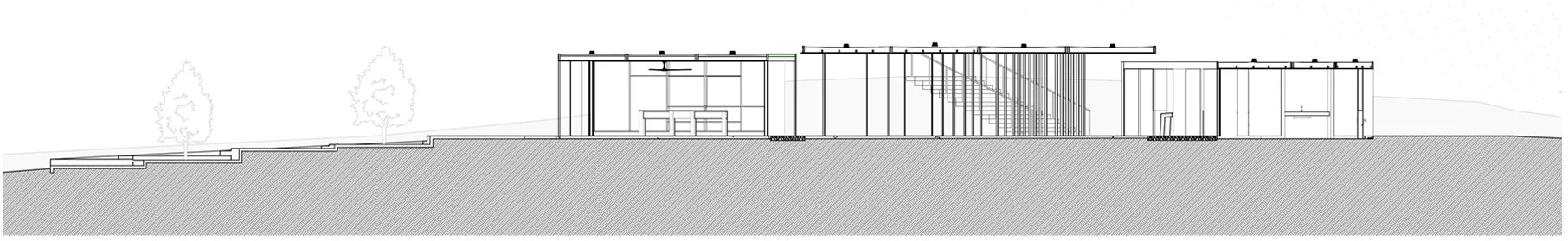

The Sharon Fieldhouse sits on a hillside defined by a series of terraced baseball fields. It marks the land as a linear incision that cuts across the site and serves as a primary axis of pedestrian circulation. The building is fissured into three elements to allow the site’s circulation to weave it’s way in and around the occupied spaces. The entrance to the Fieldhouse is an arrangement of massive concrete steps, serving as a playful procession and an informal gathering space. Spaces within the incision are delineated by vertical steel screens that fan-out and range in density to create varying levels of intimacy.

White laminated glass bathes the interior spaces with even natural light. Nested between the concession kitchen and the restrooms, a shade pavilion slips out of line, offering a cool repose overlooking the field. The openness of the screens allows breezes to pass through as well as views to the surrounding mountains. The pavilion space steps toward the field with a series of faceted grass seating terraces, inviting spectators to sit and enjoy the game. In this rich natural landscape transparent forms and subtle details imbue the architecture with a peaceful presence, a magical atmosphere for community gatherings.

design/buildLAB

The design/buildLAB is a project-based experiential learning program at Virginia Tech focused on the research, development and implementation of innovative construction methods and architectural designs. A team of 16 students collaborated with the local community of Sharon, VA, engineers, craftsmen and industry specialists to realize the Sharon Fieldhouse. The design process began with individual proposals, catalyzing an iterative process in which the best ideas from each design are combined to produce six to eight revised schemes. Eventually, the studio approaches three proposals which all inform a final scheme that is developed by the entire team.

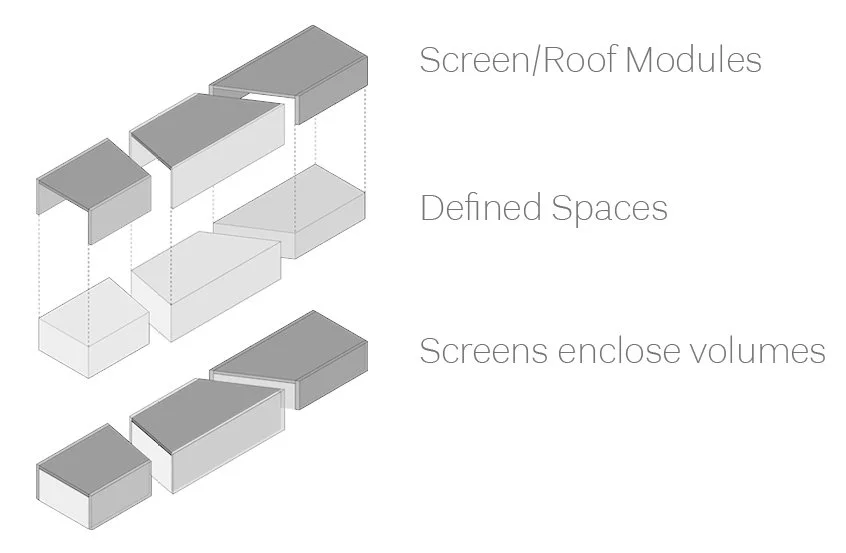

As the final scheme is being developed, the team began creating a set of construction documents for the project. Material acquisition, budget, project schedule and shop drawings were completed by the team in order to create a comprehensive picture of what it will take to complete the project under the constraints of time and budget. In conjunction with this process the prefabrication of building components is conducted at the Environmental Systems Laboratory at Virginia Tech. By mid-May, the prefabricated modules were shipped to the site where students had prepared the foundations and majority of the site to begin assembling the major components of the building.

Professors: Marie Zawistowski, Keith Zawistowski

Student Team: Mitch August, Forrest Bibeau, Ellie Burns, Chanel Carter-Harris, Barbara Dior Kane, Mykayla Fernandes, Xiao Fu, John Iaconis, Kellen McGinley, Ryan Myers, Tom Powers, Nancy Redenius, Julia Vasquez, Molly Vaughan, Landon Williams